- Home

- Products

- Industrial

- MC Cable

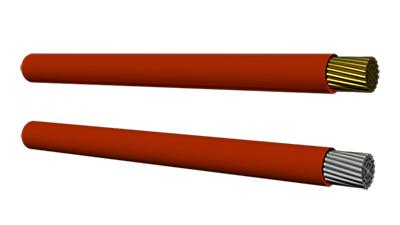

Type MC Cable, Metal Clad Cable

Metal clad cable is constructed with type XHHW-2 compact stranded AA-8000 series aluminum alloy conductors and sunlight, abrasion, water and heat resistant XLPE insulation. The conductors are wrapped using a binder tape and enclosed in an aluminum interlocked armor.

Type XHHW-2 MC cable is to be used at a maximum conductor temperature of 90℃ in dry, damp or wet locations. The voltage rating is 600 volts.

MC cable can be used in feeder and branch circuits as noted in the NEC. It is also ideal for uses in industrial, commercial or residential buildings as well as in chemical industries.

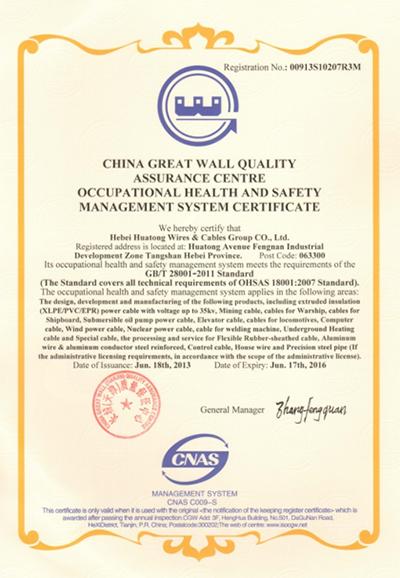

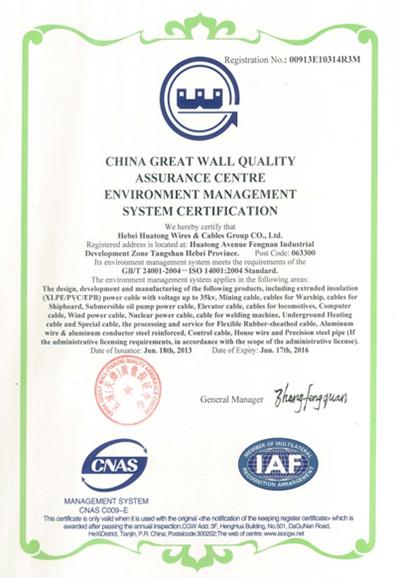

Our MC cable meets UL 1569 and UL 44 standards. It has passed the following tests: crush test, tensile test of the armor, cable density test, dielectric withstand test, FT2 flame test, insulation-resistance test, capacitance testing and other cable testings as listed in UL 1569 and UL 44.

| Conductor Size | Nominal Cond. Diameter | Insulation Thickness | Nominal Diameter | Approx. Weight | Allowable Ampacities | |||||

| (AWG or kcmil) | Inch | mm | mils | mm | mils | mm | Kg/Km | LBS/1000FT | 75℃ | 90℃ |

| 6-6-6-6 | 0.169 | 4.29 | 45 | 1.14 | 821 | 20.8 | 421 | 283 | 50 | 55 |

| 4-4-4-6 | 0.213 | 5.41 | 45 | 1.14 | 906 | 23 | 521 | 350 | 65 | 75 |

| 2-2-2-6 | 0.268 | 6.81 | 45 | 1.14 | 1017 | 25.8 | 667 | 448 | 90 | 100 |

| 2-2-2-4 | 0.268 | 6.81 | 45 | 1.14 | 1033 | 26.2 | 693 | 465 | 90 | 100 |

| 1-1-1-4 | 0.299 | 7.59 | 55 | 1.4 | 1133 | 28.8 | 824 | 553 | 100 | 115 |

| 1/0-1/0-1/0-4 | 0.336 | 8.53 | 55 | 1.4 | 1208 | 30.7 | 948 | 637 | 120 | 135 |

| 2/0-2/0-2/0-4 | 0.376 | 9.55 | 55 | 1.4 | 1294 | 32.9 | 1099 | 739 | 135 | 150 |

| 3/0-3/0-3/0-4 | 0.423 | 10.74 | 55 | 1.4 | 1396 | 35.4 | 1287 | 865 | 155 | 175 |

| 4/0-4/0-4/0-2 | 0.475 | 12.07 | 55 | 1.4 | 1509 | 38.3 | 1548 | 1040 | 180 | 205 |

| 250-250-250-2 | 0.52 | 13.21 | 65 | 1.65 | 1648 | 41.9 | 1802 | 1211 | 205 | 230 |

| 250-250-250-3/0 | 0.52 | 13.21 | 65 | 1.65 | 1692 | 43 | 1953 | 1313 | 205 | 230 |

| 300-300-300-2 | 0.57 | 14.48 | 65 | 1.65 | 1756 | 44.6 | 2054 | 1381 | 230 | 260 |

| 350-350-350-2 | 0.616 | 15.65 | 65 | 1.65 | 2013 | 51.1 | 2462 | 1655 | 250 | 280 |

| 350-350-350-1 | 0.616 | 15.65 | 65 | 1.65 | 2013 | 51.1 | 2486 | 1671 | 250 | 280 |

| 400-400-400-1 | 0.659 | 16.74 | 65 | 1.65 | 2106 | 53.5 | 2747 | 1846 | 270 | 305 |

| 500-500-500-1 | 0.736 | 18.69 | 65 | 1.65 | 2271 | 57.7 | 3241 | 2178 | 310 | 350 |

| 500-500-500-2/0 | 0.736 | 18.69 | 65 | 1.65 | 2271 | 57.7 | 3309 | 2224 | 310 | 350 |

| 500-500-500-3/0 | 0.736 | 18.69 | 65 | 1.65 | 2271 | 57.7 | 3357 | 2256 | 310 | 350 |

| 600-600-600-1 | 0.813 | 20.65 | 80 | 2.03 | 2503 | 63.6 | 3853 | 2590 | 340 | 385 |

| 600-600-600-1/0 | 0.813 | 20.65 | 80 | 2.03 | 2503 | 63.6 | 3883 | 2610 | 340 | 385 |

| 700-700-700-1/0 | 0.877 | 22.28 | 80 | 2.03 | 2642 | 67.1 | 4403 | 2960 | 375 | 425 |

| 750-750-750-1/0 | 0.908 | 23.06 | 80 | 2.03 | 2708 | 68.8 | 4619 | 3104 | 385 | 435 |

| 750-750-750-3/0 | 0.908 | 23.06 | 80 | 2.03 | 2708 | 68.8 | 4704 | 3161 | 385 | 435 |

| 750-750-750-750 | 0.908 | 23.06 | 80 | 2.03 | 2887 | 73.3 | 5563 | 3739 | 385 | 435 |

| 900-900-900-250 | 0.999 | 25.37 | 80 | 2.03 | 2904 | 73.8 | 5556 | 3734 | 425 | 480 |

| 900-900-900-900 | 0.999 | 25.37 | 80 | 2.03 | 3106 | 78.9 | 6515 | 4378 | 425 | 480 |

-

Inquiry

-

Contact us

- Hebei Huatong Wires and Cables Group Co.,Ltd.

- Add.:

No. 111 Huatong AV, Fengnan District, Tangshan City, Hebei Province. - Contact: Daniel Hou

- Tel.: +86-315-5099616